-

Farming

FUTURELAB

Never before has man had more technology and knowledge at hand to affect their environment as efficiently as they do today. We reflect on the rapid development of construction equipment and vehicles and recognize that their efficiency and performance will be even more advanced in the future.

Prologue. We will examine how the role of men is changing within the environment and how their working environment will also change. What influence will the trends, technical innovations, and social and cultural changes have on construction machines in the future? Conventional wisdom focuses on improvement: bigger, deeper, faster, more powerful, safer, and cheaper. These efforts for improvement will face natural, physical, or normative boundaries . Thus, for example, the maximum width of vehicles will be limited by the transportation infrastructure, and vehicle performance will depend on the resilience of the materials used. In evolution we observe adaptation to normal environmental conditions besides the disruptive changes brought about by spontaneous mutations or sudden, dramatic environmental changes. Regarding industry, we recognize comparable impulses in upcoming trends and technical innovations that have disruptive potential for the world of construction and mining machines. We are approaching the possible impact of such disruptive pulses through “design fictions” and “scenarios” in which we describe and illustrate future changes - trends, innovations, and pulses. Join us on a trip to the future!

The focal points of our analysis are as follows: (I) Expansion of visual and other cognitions [sensual sensations] and the physical form: head-mounted displays (Oculus Rift), ubiquitous computing (Google Glass), drone technology, augumented reality, action cams, exoskeletons, teleworking / robotics: robotics (general), telesurgery (Da Vinci robotic surgery), tele-research (Nasa Curiosity, deep sea research), and military applications.

(II) Social and political requirements: human-centered design, ergonomics, communications, gamification, sustainability, cost efficiency, energy efficiency, and crowd working. Technical impulses: lightweight, networking, autonomous driving, sensors, Internet of things, swarm logic, rapid manufacturing, Segway.

Designficitions and scenarios. Networking sensors, artificial intelligence, real-time simulation, and sensors have become ubiquitous, smaller, and cheaper. In addition, steadily improved algorithms for processing large amounts of data are available right up to AI-applications, such as artificial neural networks. What applications are conceivable if construction machines compile considerably more information about their position, motion, and environment and process this data in real time? What productivity gains could be achieved once intelligent machines relieve their operator from decisions, use tools less prone to wear, or even operate autonomously?

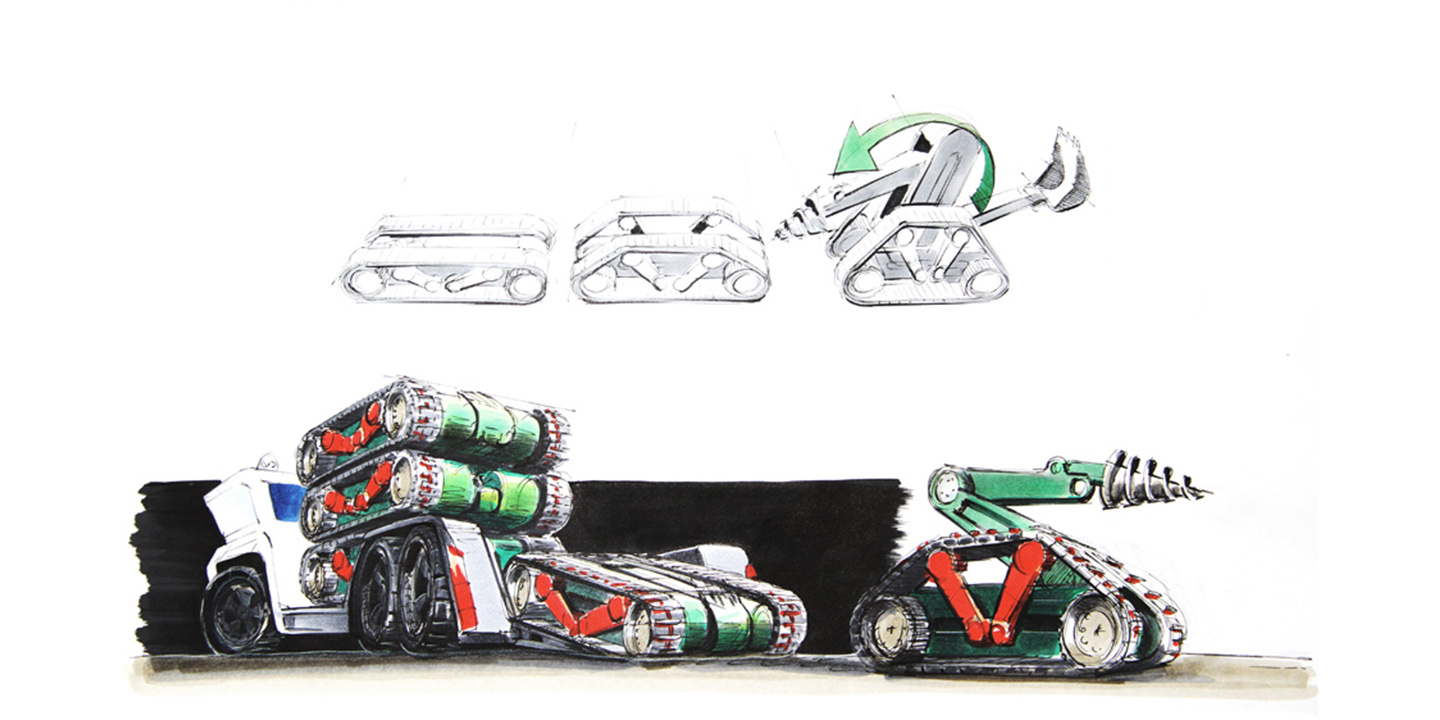

Swarm behaviour

Automated control

Environment depending locomation

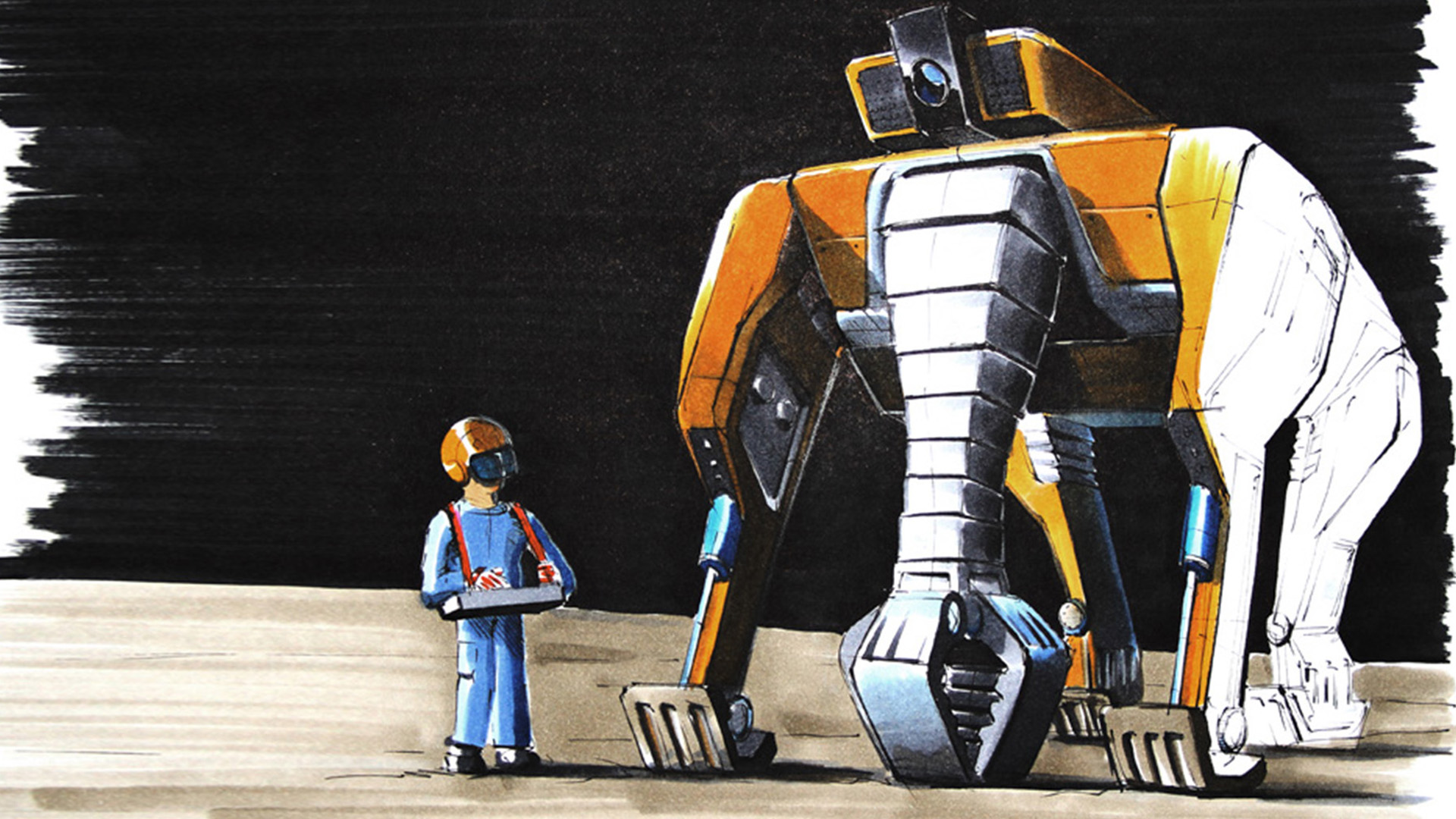

(Partly) automated control. By increasingly specialized auto-controllers and embedded systems, it will be possible to manage complex processes that were previously reserved only to men with years of training. An example would be those popular mini helicopters and quadrocopters: without the rapid development of sensor technology and electronics, these mini machines could not be flown by anyone (to fly helicopters is one of the most difficult skills to learn). Now they are available for only a few dollars, and every child is able to steer one after just a little practice. For larger machines, such controls are not yet arrived in width. You still need a high degree of training and experience because of the higher demands on system stability and security, and the smaller numbers are distributed to the cost of development. The use of human exculpatory controls are nevertheless increasingly observed to the extent that are available in the embedded systems and programming frameworks. If you watch a machine operator as an excavator operator at work, it is striking that considerable time is lost in action that is not directly productive but serves to stabilize his device or to attain a more favorable starting position for further work. Up to 60% more productivity could be achieved if support control tasks could be carried out independently and the operator focus instead on actual tasks. In the future, excavators and similar devices will be partially automated through supporting systems and will be faster and easier to use. Their movements will be smoother and more efficient. We will see robots at construction sites that work hand in hand with workers and always have a picture of their environment through radar and other sensors. In robotics, such systems are already in use today and are becoming significantly cheaper. The benchmark for walking robots is represented by devices developed by Boston Dynamics. Although Boston Dynamics focuses on military equipment, the technology used in developing these robots will also influence other areas.

AR / VR Vision. The first 3D glasses will reach the consumer market in 2016. Microsoft has developed spectacles for professional users that fade graphics into the user’s view, ensuring that perception is seamlessly complemented and enriched. In cars, more and more advanced features will improve driver performance. These applications will also be used in heavy equipment and make operation easier and safer.

Construction in existing buildings. More and more people will move to cities, where space is limited. The result is that more and more construction will involve existing buildings, with the following consequences: (a) little space, (b) problems with exhaust fumes, and (c) noise. What effect will these changes have on equipment of the future?

to be continued…

As designers we aspire to shape the future. In order to do so we like to explore interesting current topics and examine the latest solution approaches to problems in various fields. Our innova¬tion concepts strive to create an avant-garde scenario for future design opportunities.

If you like to learn more about our FutureLAB please do not hesitate to contact us.

kontakt@aroma-id.de